Steel smelting

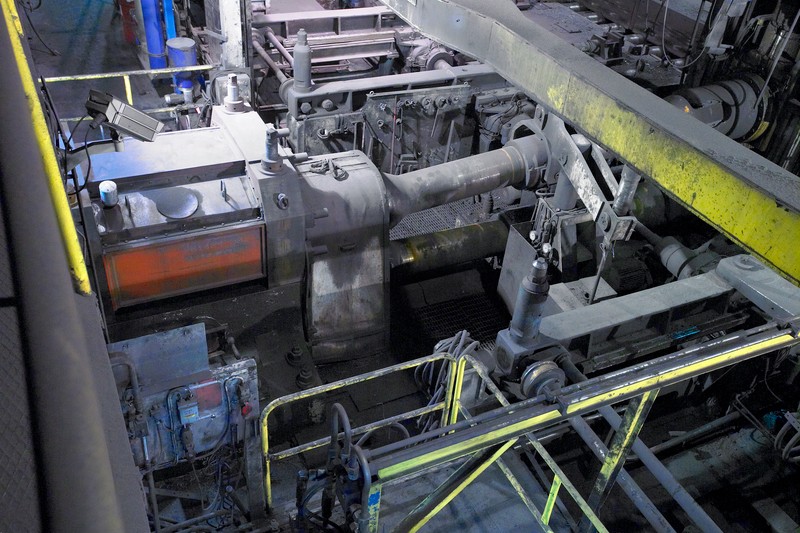

There are many kinds of metallurgical equipment, not only the equipment required by the raw material plant, but also the equipment required from the upstream process to the downstream process such as the steelmaking process, the steel rolling process, and the leveling process. These devices are equipped with various bearings. These bearings are used under the unique "iron powder", "water" and "hot" conditions of metallurgical equipment, and also meet the requirements of "heavy load + vibration and shock", "from ultra-low speed to high speed + rapid acceleration and deceleration", etc. conditions, used in the very harsh conditions it holds.

The steel smelting process is extremely harsh. The equipment needs to operate in an environment with temperatures up to 3000C, loads of 3000 tons, extremely slow swings, peak loads and vibrations. Every day, it faces high temperatures, large amounts of cooling water and high impact forces, and has to withstand constant Increased yield requirements, and the challenge of maintaining or even improving the quality of finished products, while operators are under pressure to cut unit costs, improve product quality, and reduce environmental impact, are challenges for an industry that is no longer easy to produce reliably and safely on a daily basis It can be described as sever

Temperature and speed limits, constant high shock loads, abrasive dust, corrosive chemicals and high humidity are the extreme conditions faced by plants in the metallurgical industry, and it is safe to say that these are challenges rarely encountered in other industries. It causes equipment aging, unplanned downtime, and even under the best of circumstances, makes effective maintenance difficult, and increasingly stringent environmental and health and safety regulations make environmental protection and employee safety a top priority.

Faced with pressure to increase output and improve steel quality, equipment needs to meet the demands of increased dimensional accuracy, improved surface quality, improved steel grades and production speeds, while at the same time overcoming the challenges of high precision, high loads, high speeds and corrosive coolants. The daily challenge of reducing unplanned downtime and production disruptions, reducing labor and spare parts costs, extending service and maintenance intervals, eliminating manual lubrication of lubrication points in harsh service areas, reducing risk and incidents.

Protecting your equipment from contamination and corrosion, our bearings and lubrication systems are tailored to your specific needs, and we can help you adapt and even improve quality, reliability and uptime as production demands continue to increase.

Recommend

-

-

QQ Zone

-

Sina Weibo

-

Renren.com

-

Douban